Source:

Date:2022-08-30

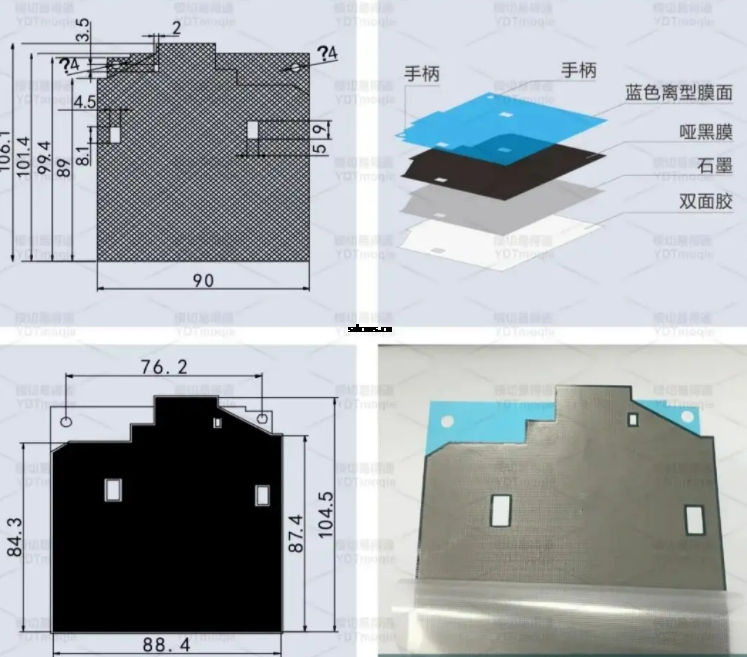

In fact, the graphite heat sink itself is conductive, and after being coated, it can achieve the effect of insulation. However, the size of each product of each customer is different, so the graphite sheet material must be cut or punched into the product size required by the customer, then the graphite powder will fall off. The meaning of wrapping, Gu Mingsi suggested, is to wrap the graphite sheet to prevent the graphite powder from falling off. If it is used by customers for heat conduction inside electronic products, if a small amount of thermal conductive graphite film falls off, it will not affect the normal operation of electronic equipment, so it is not necessary to deal with it. However, if there is a lot of falling off, if the graphite fine powder particles fall off the electronic components during use, it will cause a short circuit of the electronic components, which may cause damage to the electronic components. But under normal circumstances, the graphite sheet materials we make will be edge-wrapped. So what is his craft like?

Graphite heat sink edging process: First of all, a layer of low-viscosity silicone protective film is required, which must be silicone. Once the acrylic glue is attached, it will not be easy to remove. Two pieces of PET above 75um are pasted on both sides of the silicone protective film. The main function is to turn the positioning hole to the other side, paste the graphite in the middle, then punch the graphite, half, remove the shape waste, and then paste the glue of the PET substrate. The width of the glue should be enough to cover the PET on both sides, but not the empty holes, then tear off the silicone protective film on the reverse side, attach the tape of the PET base material on the other side, and then halfway from the glue surface, but need a layer of backing Oh, the whole process is completed by two sets of punching.